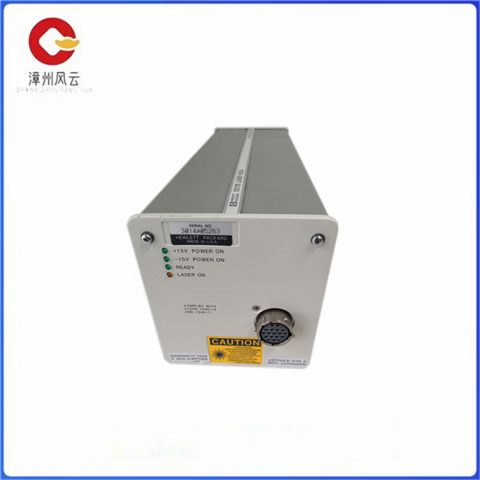

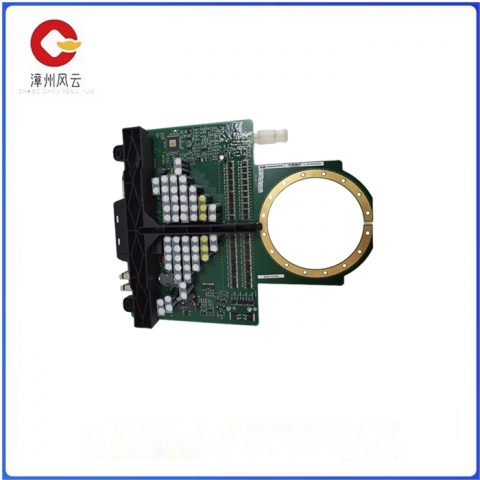

ABB THYRISTOR MODUL WE-73-10/CH 64421956: High-Power Silicon-Controlled Rectifier Module

Product Overview

The ABB THYRISTOR MODUL WE-73-10/CH 64421956 is a high-power thyristor module designed for industrial applications requiring precise control of alternating current (AC) or direct current (DC) power. As a key component in power electronics systems, it enables efficient switching, voltage regulation, and motor control in harsh industrial environments. This module combines advanced semiconductor technology with ABB’s engineering expertise to deliver reliability and performance in demanding scenarios .

Technical Specifications

| Parameter | Value |

|---|---|

| Model | WE-73-10/CH 64421956 |

| Type | Silicon-Controlled Rectifier (SCR) |

| Voltage Rating | 1200 V DC/AC (RMS) |

| Current Rating | 300 A (continuous), 1500 A (peak) |

| Gate Trigger Voltage | 1.5 V DC |

| Gate Trigger Current | 50 mA |

| Forward Voltage Drop | ≤1.8 V (at rated current) |

| Operating Temperature | -40°C to +125°C |

| Case Material | Aluminum nitride (high thermal conductivity) |

| Mounting | Press-fit or bolted to heat sink |

| Weight | 0.8 kg |

| Certifications | CE, UL, IEC 60747-3 |

.jpg)

.jpg)

.jpg)

Key Features

-

High Power Handling:

The module is engineered to manage high currents (300 A continuous) and voltages (1200 V), making it suitable for heavy-duty applications such as welding machines, DC motor drives, and industrial power supplies 19. -

Precision Control:

Its gate-triggered design allows for fine-tuned regulation of power output, ensuring stable operation in dynamic systems. The module supports phase control and rectification, enabling efficient AC-to-DC conversion . -

Thermal Stability:

The aluminum nitride housing ensures optimal heat dissipation, maintaining performance even under prolonged high-load conditions. This is critical for applications like electric arc furnaces or large-scale motor drives . -

Robust Construction:

Built to withstand extreme temperatures (-40°C to +125°C) and mechanical stress, the module is IP65-rated for protection against dust and water ingress, making it suitable for outdoor or harsh industrial settings . -

Safety and Compliance:

Compliant with international standards (CE, UL, IEC 60747-3), the module incorporates overcurrent and overvoltage protection mechanisms to prevent damage to connected equipment .

Applications

-

Industrial Motor Control:

Used in variable-speed drives (VSDs) for pumps, compressors, and conveyors to regulate motor speed and torque efficiently. Its high current capacity supports large industrial motors 210. -

Power Generation and Transmission:

Integral to high-voltage direct current (HVDC) systems for converting AC to DC power, ensuring reliable energy transmission over long distances 4. -

Welding Equipment:

Enables precise control of welding currents in arc welding machines, ensuring consistent weld quality and reducing energy consumption . -

Renewable Energy Systems:

Utilized in solar inverters and wind turbine converters to manage fluctuating power inputs and stabilize grid connections 14. -

High-Power Heating:

Controls power to resistive heaters in applications like glass manufacturing or metal heat treatment, where precise temperature regulation is critical .

Installation and Maintenance

-

Mounting:

The module must be securely attached to a heat sink using thermal interface material (TIM) to ensure efficient heat dissipation. Torque specifications for mounting bolts should be strictly followed . -

Circuit Design:

External snubber circuits (RC networks) are recommended to suppress voltage spikes and protect the module from transient overvoltages. Proper gate drive circuitry is essential for reliable triggering . -

Maintenance:

Regular inspections should check for signs of thermal degradation (e.g., discoloration of the housing) or loose connections. Cleaning dust and debris from the heat sink ensures optimal cooling performance. ABB’s diagnostic tools can monitor module health and predict potential failures 12.

Compatibility and Accessories

-

Heat Sinks:

ABB offers compatible heat sinks (e.g., ABB HS-200) designed to match the thermal requirements of the WE-73-10/CH. These heat sinks are optimized for forced-air or liquid cooling systems . -

Gate Drivers:

The ABB GD-150 gate driver module provides precise triggering signals, ensuring reliable turn-on and turn-off of the thyristor. It includes short-circuit protection and isolation features 9. -

Surge Arresters:

For overvoltage protection, ABB’s OVP-600 surge arresters can be integrated into the circuit to divert transient voltages away from the module 11.

Availability and Support

-

Warranty:

ABB provides a standard 2-year warranty covering defects in materials and workmanship. Extended warranties are available for mission-critical applications. -

Delivery:

The WE-73-10/CH is typically stocked in ABB’s global distribution centers, with lead times of 2–4 weeks for standard orders. Custom configurations may require longer lead times . -

Technical Support:

ABB’s technical service team offers 24/7 assistance for troubleshooting, firmware updates, and application-specific design guidance. Remote monitoring solutions (e.g., ABB Ability™ Condition Monitoring) are available for predictive maintenance 12.

Safety Considerations

-

Electrical Isolation:

Ensure proper isolation between the module and ground to prevent electrical hazards. Use high-voltage-rated cables and connectors . -

Thermal Management:

Avoid operating the module beyond its rated temperature limits to prevent thermal runaway. Install temperature sensors to monitor heat sink performance 9. -

Compliance:

Verify local electrical codes and standards (e.g., NEC, IEC) when integrating the module into a system. ABB’s documentation includes detailed safety guidelines .

HS:8443919090

-480x480.jpg)

There are no reviews yet.