ABB IMMFP12 Multifunction Processor Module Technical Description

Product Overview

The ABB IMMFP12 is a high-performance multifunction processor module designed for ABB’s Bailey INFI 90 distributed control system (DCS) and Symphony Plus platforms. As the computational core of automation systems, the IMMFP12 integrates advanced processing capabilities with robust communication protocols, making it ideal for mission-critical applications in power generation, oil & gas, and manufacturing. Featuring a 32-bit RISC processor and 16 MB RAM, the module delivers real-time control and data processing for complex automation tasks.

Within the INFI 90 system architecture, the IMMFP12 serves as the main module acting as the “brain” of the system, responsible for executing control logic, managing communication networks, and interfacing with human-machine interfaces. This module supports connection to I/O sub-modules via a sub-bus, enables data exchange between processor modules through control channels, and can connect up to 64 analog control stations through station chains. The modular design and scalability of IMMFP12 allow it to flexibly adapt to industrial automation needs of different scales, ensuring every operational detail is monitored, optimized, and protected within the process control hierarchy.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IMMFP12 |

| Manufacturer | ABB |

| Product Type | Multifunction Processor Module |

| Processor | 32-bit RISC, 20 MHz clock speed |

| Memory | 16 MB RAM, 8 MB flash storage |

| Communication Protocols | Infi 90 proprietary, Modbus RTU, RS-485 |

| Data Transfer Rate | Up to 40 kbaud |

| I/O Capacity | Supports up to 256 I/O channels via expansion modules |

| Power Supply | 24 V DC (±10%), redundant inputs supported |

| Power Consumption | 12 W (typical), 15 W (max) |

| Operating Temperature | -20°C to +60°C |

| Protection Rating | IP20 |

| Physical Dimensions | 30.48 cm (H) × 17.78 cm (W) × 12.7 cm (D) |

| Weight | 0.9 kg |

Main Features and Advantages

High-Performance Processing: The ABB IMMFP12 utilizes a 32-bit RISC processor to execute control algorithms with sub-millisecond latency, making it suitable for real-time applications like turbine speed control and process loop regulation. Its dual-port RAM enables simultaneous data processing and communication, optimizing system responsiveness. The module’s 32-bit microprocessor architecture operates at 16MHz, providing substantial computing power.

Flexible Communication Capabilities: Equipped with multiple communication interfaces, the IMMFP12 supports protocol conversion between Infi 90 networks and third-party systems such as Modbus RTU devices. It can manage up to 8 communication channels simultaneously, facilitating integration with SCADA systems, HMIs, and remote monitoring platforms. The module supports communication with sub-modules via the I/O expander bus, which has a bandwidth of 500kB/s.

Redundancy and Reliability: The module supports hot-swappable redundant configurations where two IMMFP12 units operate in parallel for failover protection. This design eliminates single points of failure, ensuring continuous operation in critical processes like power plant turbine control or chemical reactor management. The rugged industrial design of the module features a vibration-resistant chassis and wide temperature tolerance (-20°C to +60°C), while its EMI/EMC compliance ensures stable operation near high-voltage equipment.

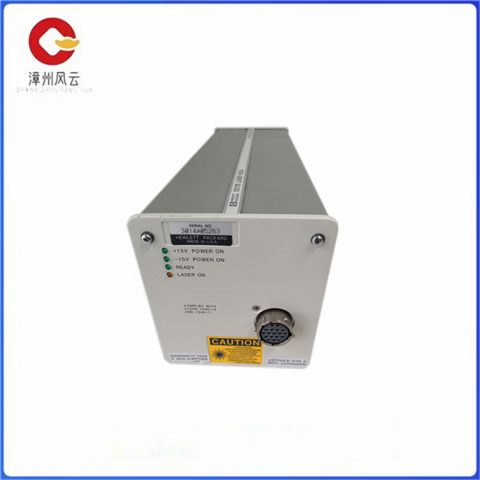

Easy Integration and Programming: Using ABB’s Control Builder M software, engineers can remotely configure the IMMFP12 for custom control logic, firmware updates, and diagnostic monitoring. The module’s standardized programming interfaces such as IEC 61131-3 languages simplify integration into existing automation ecosystems. The front panel is equipped with LED status indicators and STOP/RESET switches for easy operation and troubleshooting.

Application Areas

Power Generation: The ABB IMMFP12 is critical for managing steam turbine governors, generator excitation systems, and grid synchronization in power plants. Its real-time processing capabilities enable precise control of boiler feedwater pumps and cooling systems, optimizing energy efficiency and reducing emissions. In turbine control applications, the IMMFP12 can work in coordination with IMHSS03 hydraulic servo sub-modules for precise speed control and valve positioning.

Oil & Gas Industry: In refineries and offshore platforms, the module controls complex processes like distillation column operations, pipeline pressure regulation, and safety interlocks. Its redundancy features ensure uninterrupted operation in hazardous environments, while high-speed communication supports integration with emergency shutdown (ESD) systems. The IMMFP12 can handle various analog and digital signals, meeting the high reliability and safety requirements of the petrochemical industry.

Manufacturing Automation: The IMMFP12 powers robotic assembly lines, conveyor systems, and quality control processes in automotive and electronics manufacturing. Its ability to manage multiple I/O channels allows for seamless coordination of sensors, actuators, and vision systems, improving production efficiency and product quality. The module supports multiple function codes capable of handling everything from simple PID adjustments to complex adaptive control strategies.

Water and Wastewater Treatment: The IMMFP12 optimizes water treatment processes by controlling pump speeds, chemical dosing systems, and clarifier mechanisms. Its reliability ensures continuous operation in water distribution networks and wastewater treatment plants, supporting environmental compliance and resource conservation. The module’s non-volatile memory preserves configuration data, ensuring quick system recovery after power outages.

Related Products

IMMFP11: A predecessor model with similar functionality but lower memory capacity, suitable for smaller-scale applications

IMDS014: A 16-channel digital output module that pairs with the IMMFP12 for discrete control in automation systems

IMFEC12: A high-level analog input module that interfaces with the IMMFP12 for precise signal acquisition in process monitoring

INICT12: A computer interface module that handles communication between the IMMFP12 and host computers

IMHSS03: A hydraulic servo slave module that works with the IMMFP12 in turbine and heavy machinery control applications

IMASI23: An analog input sub-module that provides analog signal input interface for the IMMFP12

IMASO11: An analog output sub-module that expands the analog control output capability of IMMFP12

BRC300/400: Multifunction controllers belonging to the same ABB control system product line as IMMFP12

Installation and Maintenance

Installation Preparations: Before installing the ABB IMMFP12, verify the power supply meets 24 V DC ±10% requirements and ensure the mounting panel is grounded. Use shielded cables for communication connections to minimize EMI, and secure the module to a DIN rail using torque screws (1.5-2.5 N·m) to withstand vibration. For redundant setups, connect two IMMFP12 units via dedicated redundancy cables as per ABB’s guidelines. Confirm module version compatibility with your system configuration and firmware, and insert it precisely into the designated processor slot in the INFI 90 cabinet backplane.

Maintenance Recommendations: Regularly inspect the module’s LED indicators for power, communication, and fault status. Use ABB’s Control Builder M software to monitor processor load and update firmware quarterly. Clean the module’s vents with compressed air every six months to prevent dust accumulation. For preventive maintenance, replace electrolytic capacitors every 5-7 years to ensure long-term reliability. In the event of a fault, refer to the module’s diagnostic display to identify issues and consult ABB’s technical support for replacement procedures.

Product Guarantee

ABB warrants the IMMFP12 against defects in materials and workmanship for 1 year from purchase. This includes free repair or replacement of faulty components, supported by ABB’s global network of certified technicians. Customers receive 24/7 technical support for installation, configuration, and troubleshooting, with remote assistance available via secure VPN. ABB’s Extended Service Agreement offers proactive maintenance, firmware updates, and priority spare parts delivery for up to 5 years, ensuring continuous system reliability. The IMMFP12 complies with CE, UL, and ROHS standards, providing peace of mind in safety-critical applications. ABB’s commitment to industrial cybersecurity ensures ongoing software updates to address emerging threats and maintain compliance with evolving industry requirements.

There are no reviews yet.