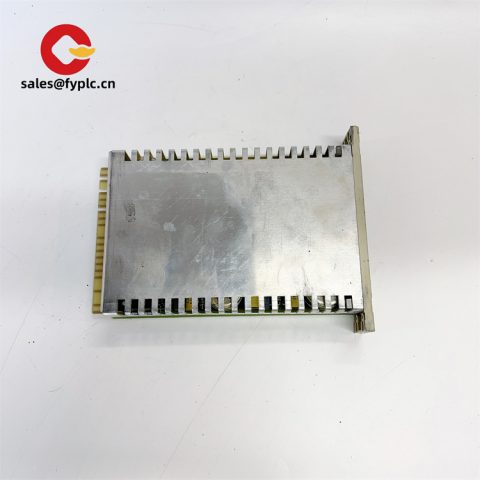

ABB DTDX991A

Product Description

The ABB DTDX991A is a high-performance digital I/O module designed for industrial automation systems, supporting real-time data exchange and device control in complex industrial environments. It belongs to ABB’s AC500S series and is widely used in manufacturing, energy, and building automation systems 15.

Core Functions

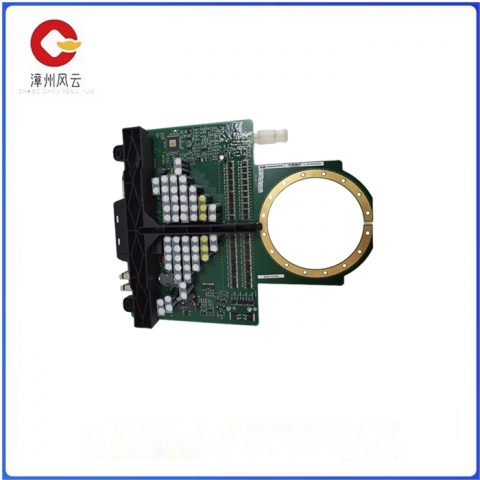

- Signal Processing: Features 8 digital inputs and 8 digital outputs, supporting NPN/PNP signal types and relay/transistor output modes. Inputs can detect switch states or sensor signals, while outputs control actuators (e.g., solenoid valves, motors) 15.

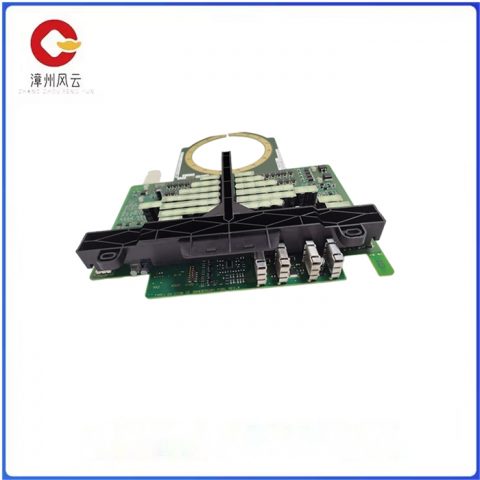

- Multi-Protocol Communication: Supports Modbus RTU/TCP, PROFIBUS DP, and CAN protocols, enabling seamless integration with controllers (e.g., AC800M) and monitoring systems 1.

- High-Speed Data Transmission: Achieves up to 12 Mbps transmission rates, ensuring rapid response in time-sensitive applications like conveyor belt control or process automation 1.

- Long-Distance Communication: RS-485 supports up to 1,200 meters of transmission, suitable for distributed control systems (DCS) in large-scale industrial facilities 1.

- Reliability Design: Redundant power supply and communication channels, plus automatic switching, ensure system continuity during faults. Real-time monitoring functions detect channel failures promptly 1.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Type | Digital I/O Module |

| Manufacturer | ABB |

| Model | DTDX991A |

| Power Supply | 24V DC ±10% |

| Input Voltage | 24V DC (NPN/PNP compatible) |

| Output Type | Relay/Transistor |

| Current Rating | 1A per channel (max 2A total) |

| Communication Interfaces | Modbus RTU/TCP, PROFIBUS DP, CAN |

| Transmission Rate | Up to 12 Mbps |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +80°C |

| Protection Class | IP20 (dustproof) |

| Dimensions (LxWxH) | 120 x 60 x 22 mm |

| Weight | 150 g |

Key Advantages

1. High Reliability

- Industrial-grade components resist electromagnetic interference and voltage fluctuations.

- Redundant design (N+1) ensures system stability in critical applications like oil refining and power plants 1.

2. Flexibility and Scalability

- Supports multiple signal types and communication protocols, adapting to diverse process requirements. For example, in chemical plants, it can simultaneously monitor reactor pressure and control material dosing 1.

- Modular design allows easy expansion of I/O channels by adding compatible modules (e.g., ABB DSDX180A) 1.

3. Easy Configuration

- ABB’s integrated software (e.g., Drive Composer) enables graphical configuration, logic diagram creation, and real-time parameter monitoring 127.

- Built-in diagnostics automatically identify channel failures, reducing maintenance time 1.

4. Energy Efficiency

- Low power consumption (3W) and a 10-year lifespan lower operational costs. Compatibility with newer ABB modules facilitates cost-effective system upgrades 1.

Applications

1. Factory Automation

- Connects production line controllers, sensors, and actuators for real-time monitoring of conveyor belt speeds and quality inspection equipment 1.

- Example: In automotive manufacturing, it controls robotic arm movements and welding equipment 1.

2. Building Automation

- Manages HVAC systems, elevators, and lighting by integrating with building management systems (BMS) 1.

- Example: Adjusts air conditioning based on occupancy sensors to optimize energy efficiency 1.

3. Power Systems

- Monitors relay states and circuit breaker status in substations, supporting smart grid applications 1.

- Example: Automatically switches power supply paths during grid failures 1.

4. Process Industries

- Controls temperature, pressure, and flow in chemical reactors and distillation units 1.

- Example: In oil refineries, it regulates crude oil heating and pressure relief valves 1.

Related Products

- ABB AI815: Analog input module supporting HART protocol, for connecting pressure/temperature sensors 1.

- ABB AO810: Analog output module for controlling regulating valves and actuators 1.

- ABB S800 I/O Communication Gateway: Enables integration with Ethernet/IP and PROFIBUS networks 1.

- ABB DSDX180A: 16-channel digital I/O module for logic control loops 1.

- ABB HART-IP Gateway: Connects wireless HART devices for Industry 4.0 applications 1.

Installation and Maintenance

Pre-Installation

- Verify compatibility with controllers (e.g., AC800M) and ensure all accessories (modules, cables, terminal blocks) are included 1.

- Install in a control cabinet with ≥5 cm ventilation space on all sides, ensuring ambient temperature remains within -20°C to +60°C 1.

Maintenance

- Periodic Checks: Inspect connections and indicator status every 6 months; update firmware as needed 1.

- Diagnostics: Use ABB system tools to monitor channel health; faulty channels automatically switch to redundant paths (if enabled) 1.

Warranty and Support

- 1-Year Warranty: Covers repair/replacement of defective components due to material or workmanship issues 1.

- Technical Support:

- Online Resources: Access manuals and firmware updates on ABB’s official website 427.

- Service Centers: Qualified engineers provide on-site diagnostics and repairs for complex issues 1.

- Delivery: Shipped globally within 3 days of payment, with secure packaging 1.

Priority Terms: Discounts and technical consulting services are available for long-term clients 1.

Summary

The ABB DTDX991A is a reliable, high-performance digital I/O module ideal for industrial automation systems requiring real-time communication and precise control. Its scalability, multi-protocol support, and robust design make it essential for factories, energy facilities, and smart buildings prioritizing efficiency and safety.

HS:7326909000

There are no reviews yet.